![]()

(reproduction time 0:12)

It is the technology of transferring from a decoration film simultaneously in a molding tool on molding process. It is used in various fields, such as cellular phones, electric appliances, cars, and cosmetic packages. It can decorate freely and beautifully on the surface of a product, metallic feeling, pearl, and lusterless and so on, and it will meet customer's various design expressions.

(reproduction time 0:09)

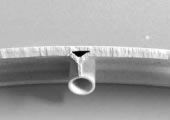

At the kept pressure process in the conventional injection molding, the pressure can not be equally applied to a molding part. It is the technique that the kept pressure can be applied equally by pouring high pressure gas (nitrogen gas) into the inside of the part in the middle of ejecting and just before the end of ejecting. Lightening the product by preventing it from the sink mark of a rib, and by making it hollow structure can realize forming thin thickness and improving adiathermancy. Moreover, it can reduce the problems of warp/sink mark which are often occurred in the conventional molding process.

An example of sink mark

prevention

An example of a

blom molding

Handle (weight saving)

The lid of a cooking-rice jar

(improvement in insulative)

(reproduction time 0:20)

It is a technique to obtain a molding product with good surface condition. Until just before being filled up with constant gas pressure into a mold tooling, foaming rate is adjusted so that resin may not be foamed more than regulation.

Speaker Cabinet

Improvement in design and cost cut are implemented by molding the resin and the metal simultaneously. It is possible to get broad designs by utilizing the strong point of each material efficiently. Since resin and metal are not pasted up, attention should be paid on the design. Moreover, it is necessary to also take into consideration the difference in the linear expansion coefficient.

The product of terminal insertion molding

The product of stainless steel insertion molding