![]()

(reproduction time 0:15)

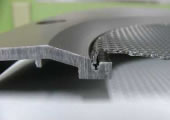

Vibration welding is the method of making resin melt and carrying out welding by using the frictional heat generated in the junction interface of two kinds of resin parts. It is also possible to weld materials in different kinds. (It may not suit) In order to obtain thermal energy, in the condition of that pressure is applied to components, one of the two components is vibrated with fixed frequency and amplitude. It is the technology used for the welding of a comparatively big product Some devices are required for the design of the joint surface form

(reproduction time 0:31)

Heat parts to be welded with contact or non-contact heat plate that has been heated beforehand. It is the technology that welding parts in two kind with giving pressure on them after joint surfacesare in melted state. It is also possible to weld materials in different kinds. (It may not suit) It has some certain flexibility on the joint surface form.

It is the welding method that taking a heat source from generating heat with turning on heavy current,the low voltage in short time to heater wires. It is used for the welding of thin sheet-like parts. Moreover, screw-fastening work can be excluded in an assembly process.

It is a welding method that the dielectric-heating action of high frequency is used and it makes internal generation of heat in welding articles (metal). It is used for welding resin parts and metal parts (a speaker network, an insertion nut). Moreover, it is possible to weld resin parts with inserting wire-like metal parts among two kinds of resin parts.

The ultrasonic vibration with lengthwise direction is given to resin parts. It raises temperature locally and momentarily by the frictional heat generating. It raises temperature locally and momentarily by the frictional heat generating. What gives vibration and pressure to a product is called “phone". There is the direct welding. It raises temperature of the portion which is touched on phone directly. And there is the transmission welding which raises temperature (frictional heat) on interface of the product and the product with the transmission of vibration through the product. The biggest advantage is that the tact time is very short.

![]()

The finished-goods process is the managed process based on thoroughness of initial flow management. It is possible to draw our own design for line equipment and a production Jig. We are doing our best to improve processes better day after day.

In order to correspond to the situation of a small lot, quick-delivery demand, and complicated processes, the assembling work members are educated being able to work at any process.