Many three-dimensional data are overflowed in public since three dimensional CAD have been increasingly spread these days.However, can it be utilized with maximum extent? We introduced high-end three dimensional CAD for product development in 1992 preceding the other companies. The three-dimensional data which we created solves the problem of each manufacturing process, and joints every process from a design to a finished-goods assembly seamlessly in one data. The designers who have all production processes in house, and have full knowledge of each process reduce loss of development by repeating a review with each section. Therefore, the product development period can be shortened rapidly.

The data created by high-end three dimensional CAD has solved all problems of the manufacturing process. Therefore, it is possible to connect in one data until the last process. Our development stance is the spot and an actuality principle. It is completely different from three-dimensional-CAD development on only shape.

Development environment

| Category | Software | |

|---|---|---|

| 3D CAD | UNIGRAPHICS | 8 |

| SOLIDWORKS | 2 | |

| Euclid | 1 | |

| 3D CAM | Euclid | 1 |

| 2D CAD | Autocad LT | 1 |

| Flow analysis |

MOLD FLOW | 2 |

| C-MOLD | 1 | |

| Intensity analysis |

COSMOS | 1 |

(reproduction time 0:32)

(reproduction time0:08)

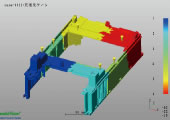

Warp is inevitable on a molded product. It is difficult to abolish the warp only by molding conditions. In our development, the warp of a product is predicted with using the flow analysis software. The example case often occurred, is in the status that only the analysis of the warp has been done but measures are not taken. What should we do? We prevent the product from the warp by modification without any affection to the product structure or the product performance.

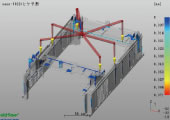

The intensity of a product is also difficult matter like the product warp. This is also solved in the beginning of development process. The product form is changed based on the result of analysis, and finish it as a proper form.